Kest – KM Mixer Magnetic Coupled

For volumes from 0,2 to 22.000 liter

Features

- Full traceability on all parts with media contact

- All tank plates are FEM Analyzed according to PED and ASME

- Zero particle shedding

- Minimize downtime

- Optional Stainless Steel cover for a clean look and good cleanability

- ATEX version available

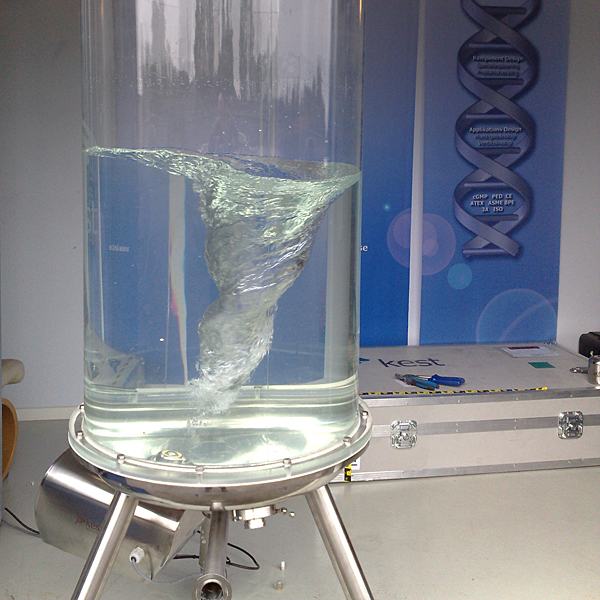

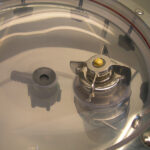

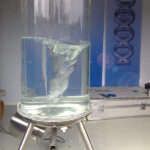

Kest Mixer is a magnetic coupled mixer with an aseptic design. Excellent mixing performance, user-friendly and able to mix to the last drop. The ideal choice for critical pharma and biotech applications where full product recovery is important.

The Kest Mixer is a bottom mounted magnetic coupled mixer and has a unique mix of intelligent controls, user-friendly design and innovative engineering. Its unique design and many powerful features provide cost efficient, low maintenance mixing processes with reliable results. Everything from its mixing head design and the bearing materials is built for one thing: perfect flow.

Full product recovery and zero particle shedding

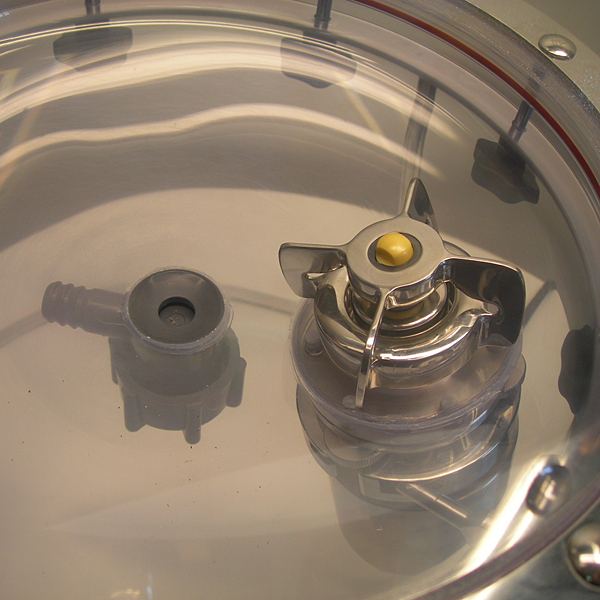

The unique mixing head design and the position of the blades close to the bottom of the tank allows the mixer to run while the tank is being emptied, which ables the mixer to mix low levels as well. Mixing to the last drop with uncompromised cleanability.

The robust bearing combination of Zirconium and Sic and the fine-tuned geometry, ensures no particle generation in your media. The higher bending strength of the zirconium material enables the male bearing to be made in one solid piece. This optimizes the aseptic design and increases the robustness and low wear property of the bearing.

Total integrity of the tank

The Mixer tank plate is machined from a solid bar. The design is FEM analyzed in comly with PED and ASME pressure vessel code. The tank plate is welded into the tank and creates a solid barrier with no risk of contamination of the media inside the tank.

Full control and minimal down time

The Kest Mixer can be equipped with an intelligent speed sensor system to control the actual movement of the mixing head in the tank. The system can detect if the mixing head is mounted in the tank, the rotation speed of the mixing head and the rotation direction.

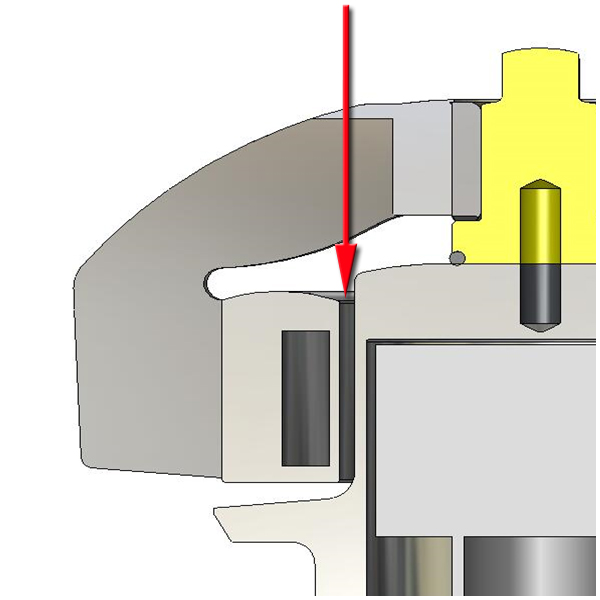

The drive unit is equipped with the patented Kest-Lock Connection that ensures quick disconnection from the tank plate during maintenance. When you put the drive unit back on the tank plate, the spring closed Kest-Lock helps the operator to hold the drive unit in place when tightening the screw.

Read more about Brand: KEST

| Sizes | 0,2 liters to 22,000 liters |

| Pressure range | -1 to 7 bar |

| Temp. range | 0°C to 150°C |

| Material | -Mixerhead: 1.4435 (316L) and Silicone carbide (SiC) -Bearing: Zirconium dioxide (ZrO2) -Tankplate: 1.4435 (316L) -Sealing EPDM or Silicone |

| Finishing | Ra ≤0.5 μm [20 µin] Polished – on surfaces with product contact |

| Electrische specifications | Depends on model type, see datasheet |

| Marking | Head and Bearing is marked with ID No. Tank plate is marked with material grade and heat number |

| Certificates | FDA, USP Class VI, 3.1, IP55 |

There is no video for this product yet, check back later.

Single-Use

Single-Use

Mixers & Pumps

Mixers & Pumps

Valves

Valves

Seals

Seals Hoses

Hoses Fittings

Fittings Tube Sealers & Welders

Tube Sealers & Welders

Transfer Ports

Transfer Ports

Validation

Validation

We utilize cookies to ensure you have the best possible experience while visiting our website.

We utilize cookies to ensure you have the best possible experience while visiting our website.