ROMYNOX Fluid Transfer Port

Maintain sterility easier

The biggest challenge of a cleanroom is maintaining sterility.

The surface of a product vessel is a devious way for microorganisms to sneak into your cleanroom.

Every time you drive your product vessel into a cleanroom, you increase the risk of contamination.

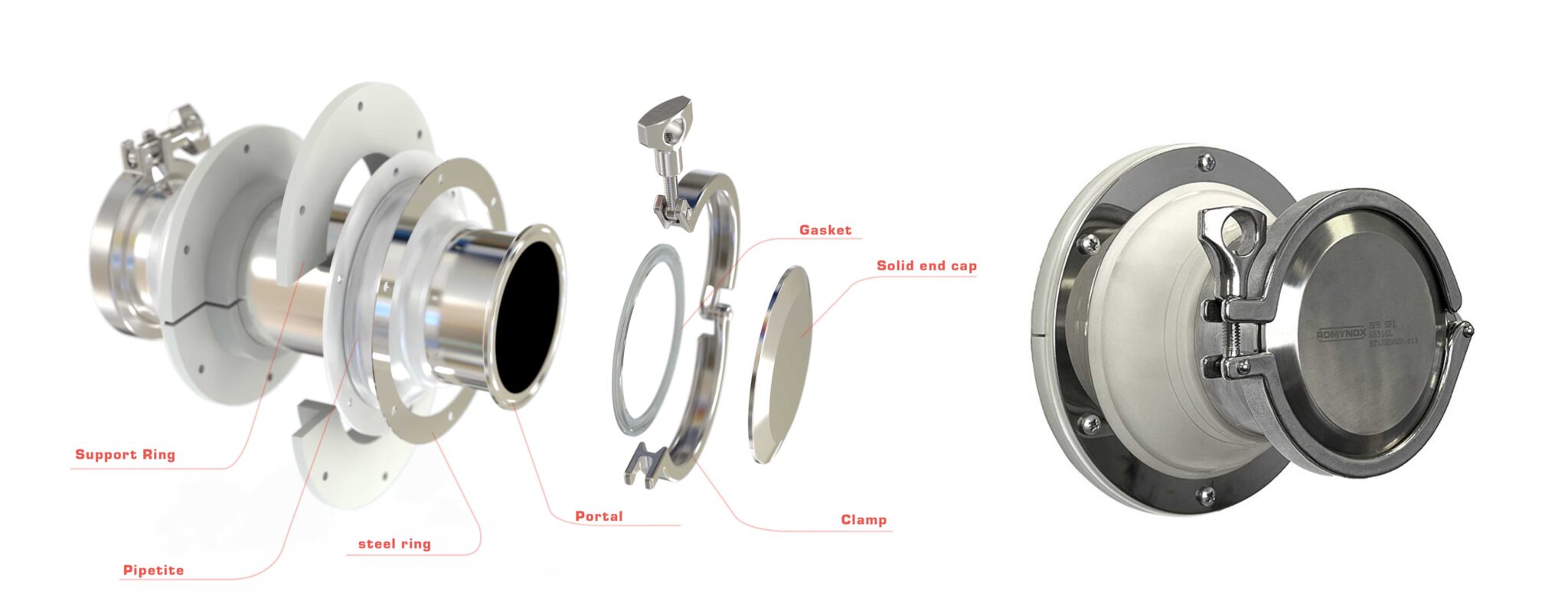

With the transfer ports from ROMYNOX, you can transfer large quantities of liquids in a cleanroom via a portal in the wall.

This solution eliminates the need for riding your product vessel in a cleanroom, reduces the passage of personnel from preparation areas to processing areas, reduces the risk of cross-contamination, breakage, or spillage, and simplifies the cleaning process.

Mousehole

Iris Valve

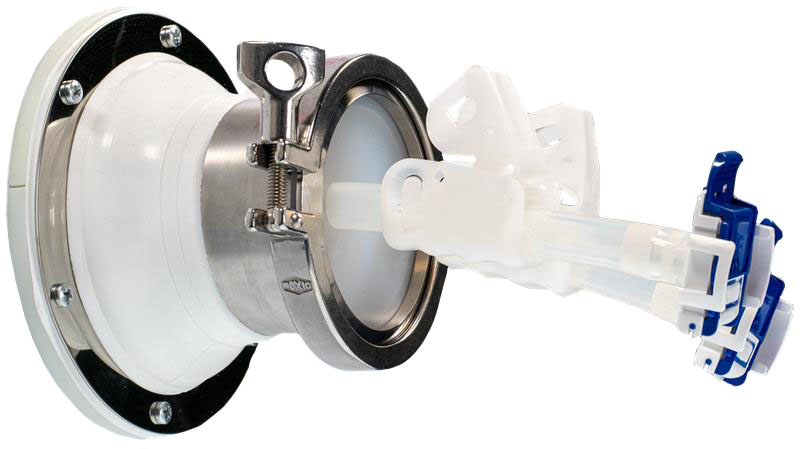

The Iris valve provides a dust-tight seal between two cleanrooms and is used in the upstream process. By simply passing a hose or tube through the Iris valve, you can keep your product vessel outside the cleanroom. The flexible and replaceable sleeve is made of EPDM, so you can use a hose regardless of thickness.

ROMY-PASS

Single-Use

Single-Use

Containments

Containments Mixers

Mixers

Pumps & Flow Measurment

Pumps & Flow Measurment

Valves

Valves

Seals

Seals

Hoses

Hoses

Fittings

Fittings

Tube Sealers & Welders

Tube Sealers & Welders

Transfer Ports

Transfer Ports

Validation

Validation

We utilize cookies to ensure you have the best possible experience while visiting our website.

We utilize cookies to ensure you have the best possible experience while visiting our website.