SURFACE FINISHES

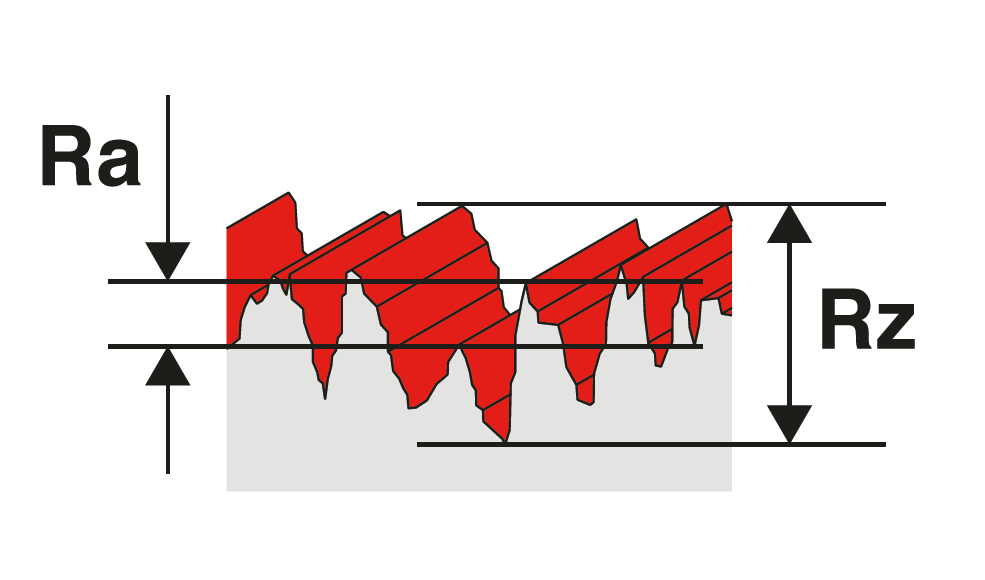

The most common parameter for surface texture is Average Roughness (Ra). Ra is calculated by an algorithm that measures the average length between the peaks and valleys and the deviation from the mean line on the entire surface within five sampling sections. Ra averages all peaks and valleys of the roughness profile and then neutralizes the few outlying points so that the extreme points have no significant impact on the final results. It’s a simple and effective method for monitoring surface texture and ensuring consistency in the measurement of multiple surfaces.

SAMPLING SECTIONS

|

Rs µm |

Section |

Total Length |

|---|---|---|

|

0.006 < Ra ≤ 0.02 |

0.08 | 0.4 |

| 0.02 < Ra ≤ 0.1 | 0.25 | 1.25 |

|

0.1< Ra ≤ 2 |

0.8 | 4 |

ASME BPE STANDARDS

Mechanically Polished

|

Surface |

Ra-Max |

Ra Max |

|---|---|---|

|

SF0 |

No Ra Req. |

No Ra Req. |

|

SF1* |

20 |

0.51 |

|

SF2 |

25 |

0.64 |

|

SF3 |

30 |

0.76 |

Mechanically Polished & Electropolished

|

Surface |

Ra-Max |

Ra Max |

|---|---|---|

|

SF4* |

15 |

0.38 |

|

SF5 |

20 |

0.51 |

|

SF6 |

25 |

0.54 |

*Most Common

Another parameter used for roughness is Mean Roughness depth (Rz). Rz is calculated by measuring the vertical distance from the highest peak to the lowest valley within five sampling lengths, then averaging these distances. Rz averages only the five highest peaks and the five deepest valleys—therefore extremes have a much greater influence on the final value.

The specification according to the ASME-BPE includes seven surface finishes that may be used when specifying surface finishes.

DIN 11865 STANDARDS

Mechanically Polished

|

Surface |

Ra-Max |

Ra Max |

|---|---|---|

|

H1 |

< 1.6 μm |

< 3.2 μm |

|

H2 |

< 0.8 μm |

< 3.2 μm |

|

H3 |

< 0.8 μm |

< 0.8 μm |

|

H4 |

< 0.4 μm |

< 0.4 μm |

|

H5 |

< 0.25 μm |

< 0.25 μm |

Mechanically Polished & Electropolished

|

Surface |

Ra-Max |

Ra Max |

|---|---|---|

|

H3 |

< 0.8 μm | < 0.8 μm |

|

H4 |

< 0.4 μm | < 0.4 μm |

|

H5 |

< 0.25 μm |

< 0.25 μm |

Single-Use

Single-Use

Isolators

Isolators

Mixers

Mixers

Pumps & Flow Measurment

Pumps & Flow Measurment

Valves

Valves

Seals

Seals

Hoses

Hoses

Fittings

Fittings

Tube Sealers & Welders

Tube Sealers & Welders

Transfer Ports

Transfer Ports

Validation

Validation

We utilize cookies to ensure you have the best possible experience while visiting our website.

We utilize cookies to ensure you have the best possible experience while visiting our website.