ROMYNOX SERVICES

Choose Romynox's as your favorite partner with extra services based on knowledge, added value, precision and efficiency. Elevating your high purity processes to new heights of excellence with the Romynox suite of services:

Torque Tools

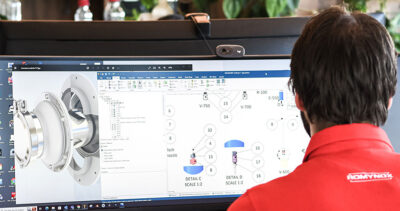

3D CAD Design

Leverage our custom component solutions, where innovation meets precision. Our skilled engineers harness advanced 3D CAD technology to craft bespoke solutions, turning complex challenges into streamlined successes.

Hose Assembly

ROMYNOX WAREHOUSE KARDEX SYSTEM

The Kardex system is one of our most important assets to achieve our goal of having zero preventable mistakes.

Our Kardex shuttle is a storage and retrieval system that maximizes storage capacity, storage quality, and order-picking speed.

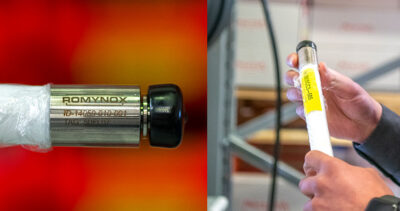

Laser Engraving

Discover the clarity and permanence of our laser engraving, where every mark signifies our commitment to quality and traceability, enhancing the identity and longevity of your components.

Remote Assistance

Bridge distances instantly with our cutting-edge remote assistance, powered by the HMT-1 device. This hands-free solution brings our expertise directly to your site, solving complex issues in real-time with unparalleled efficiency.

Single-Use

Single-Use

Isolators

Isolators

Mixers

Mixers

Pumps & Flow Measurment

Pumps & Flow Measurment

Valves

Valves

Seals

Seals

Hoses

Hoses

Fittings

Fittings

Tube Sealers & Welders

Tube Sealers & Welders

Transfer Ports

Transfer Ports

Validation

Validation

We utilize cookies to ensure you have the best possible experience while visiting our website.

We utilize cookies to ensure you have the best possible experience while visiting our website.