Containment Transfer Systems

Efficient and contained powder transfer for pharmaceutical production with Ezi-Flow™ CSV systems that prioritise operator safety, sterility and process integration.

High-Containment Powder Transfer Solutions in Pharmaceutical Production

A New Approach to Operator Protection and Efficient Powder Transfer

Handling potent powders in pharmaceutical production demands high-containment solutions to ensure full operator protection, minimise exposure risks, and prevent contamination. Ezi-Dock introduces an alternative approach with its Ezi-Flow™ CSV systems, offering an innovative containment transfer solution focused on safety, efficiency, and seamless integration into existing processes. These systems provide a fully enclosed transfer method, enhancing productivity while reducing reliance on personal protective equipment (PPE) and secondary containment barriers, addressing common challenges in powder handling.

Understanding Ezi-Flow™ CSV Systems

Containment transfer systems play a critical role in pharmaceutical manufacturing, enabling the safe transfer of active pharmaceutical ingredients (APIs) and other high-potency compounds. Traditional powder transfer solutions, such as Containment Split Butterfly Valves from ChargePoint or Andocksysteme Butterfly Valves, have long been industry standards. However, Ezi-Flow™ CSV systems present a lightweight and cost-effective alternative, optimising powder flow, ensuring containment, and maintaining regulatory compliance for pharmaceutical applications.

Understanding Containment in Pharmaceutical Powder Transfer

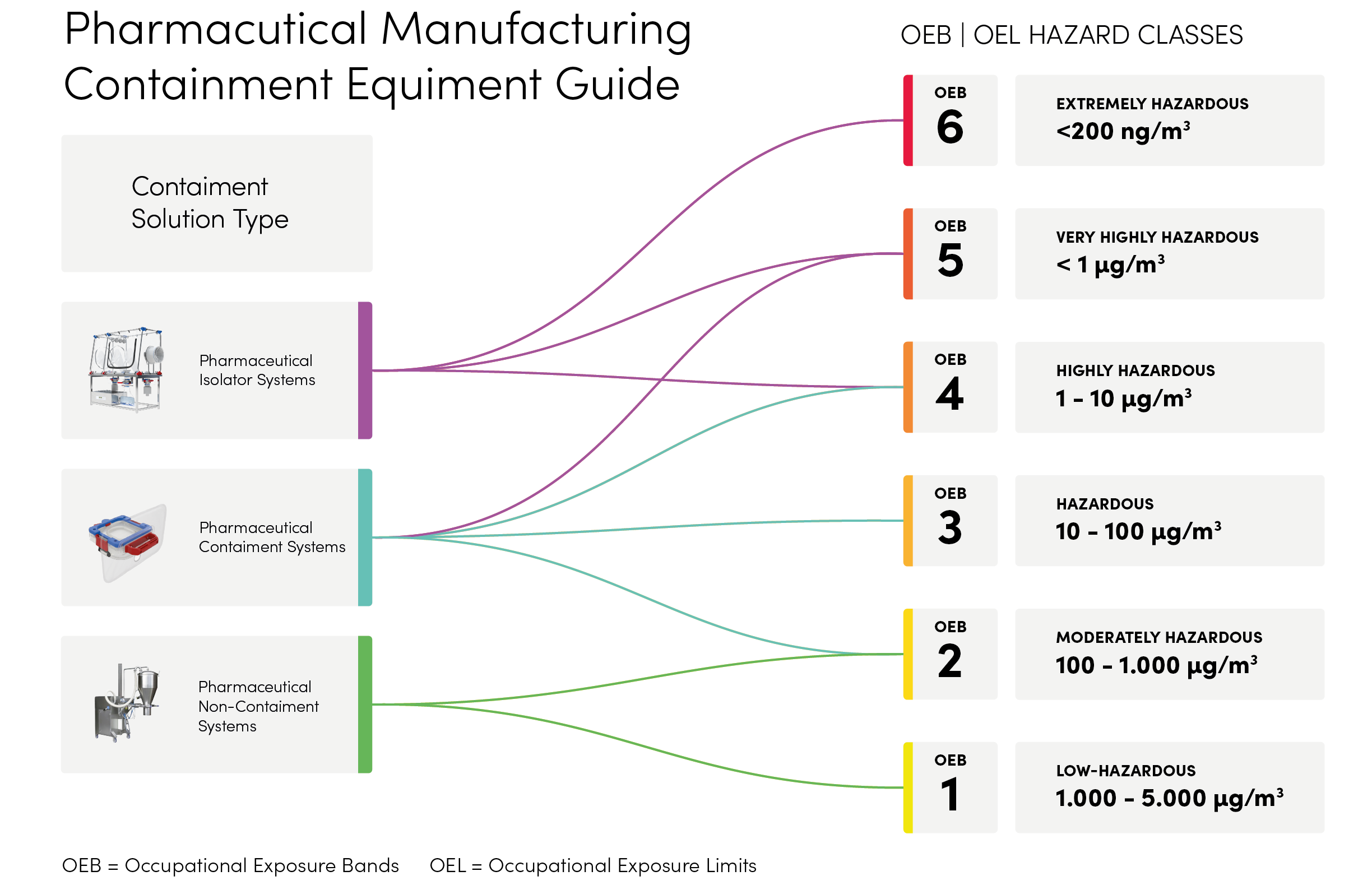

Pharmaceutical containment requirements are defined by Occupational Exposure Bands (OEB) and Occupational Exposure Limits (OEL), ranging from low-hazard to extremely hazardous materials. Selecting the right technology—isolators, high-containment transfer systems, or single-use closed devices—ensures operator safety, product integrity, and compliance with GMP, FDA, and EMA standards.

Romynox provides solutions across all OEB levels, helping manufacturers control potent powders, reduce cross-contamination risk, and streamline validated processes.

Key Benefits of Ezi-Flow™ CSV Systems

Enhanced Operator Safety

Provides complete containment of potent powders, significantly reducing operator exposure to hazardous substances. With an OEB 5 rating and exposure levels of <1µg/m³, it ensures minimal airborne contamination, maximising operator safety.posure and the reliance on PPE or secondary containment barriers.

Compact and User-Friendly Design

Lightweight and space-efficient, allowing for straightforward installation without the need for extensive modifications or additional containment infrastructure.

Material Loss and Yield Optimisation

Enhances powder flow efficiency, reducing material loss and ensuring higher yields in pharmaceutical processes.

Sterility and Cleanability

Designed to meet stringent pharmaceutical hygiene requirements, supporting sterilisation and minimising contamination risks in critical applications.

Seamless Process Integration

Designed for easy implementation within existing pharmaceutical workflows, ensuring process continuity and regulatory compliance.

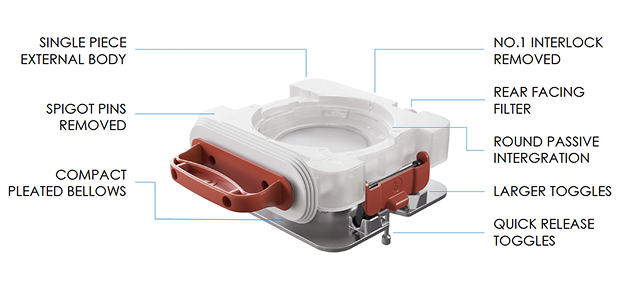

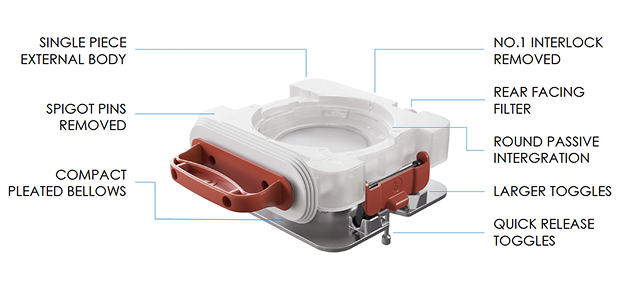

The New Improved

Ezi-Dock CSV MK5

Excel in operator safety

Handling biopharmaceutical powders requires strict containment measures to maintain sterility, prevent cross-contamination, and ensure operator safety. In pharmaceutical production, containment transfer solutions must meet stringent industry standards while offering flexibility for different applications. Chargebags and process bottles play a crucial role in controlled powder transfer, reducing contamination risks and supporting high-integrity material handling.

|

Enhanced CSV Active UnitDesigned for single-use, flexible containment, chargebags provide a cost-effective and disposable solution for handling APIs and other fine powders. Ezi-Dock chargebags come in various configurations. As alternatives, ChargePoint ChargeBag® and GEA Hicoflex® charge bags have set industry benchmarks. Their lightweight design simplifies handling while ensuring maximum protection for both operators and products, making them ideal for high-containment applications that require minimal cross-contamination risks. These bags integrate seamlessly with Ezi-Dock CSV systems and offer Tri-Clamp options, ensuring compatibility with different systems. |

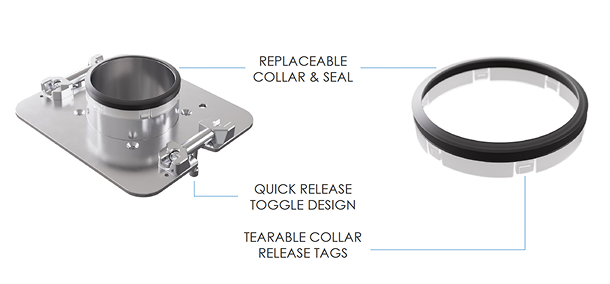

Upgraded MK5 SpigotHigh-Density Polyethylene (HDPE) process bottles provide a robust and cost-effective solution for pharmaceutical powder storage and transfer. Ezi-Dock offers its own unique chargebag alternative alongside industry-standard solutions like ChargePoint PuroVaso® plastic containers. HDPE bottles are well-suited for aseptic powder handling in biopharmaceutical environments. Their durable, chemically resistant design ensures safe containment while minimising material waste. These bottles offer environmental protection, ease of handling, and seamless transport, making them particularly valuable in aseptic environments where sterility and containment integrity are paramount. |

|

|

Enhanced CSV Active UnitDesigned for single-use, flexible containment, chargebags provide a cost-effective and disposable solution for handling APIs and other fine powders. Ezi-Dock chargebags come in various configurations. As alternatives, ChargePoint ChargeBag® and GEA Hicoflex® charge bags have set industry benchmarks. Their lightweight design simplifies handling while ensuring maximum protection for both operators and products, making them ideal for high-containment applications that require minimal cross-contamination risks. These bags integrate seamlessly with Ezi-Dock CSV systems and offer Tri-Clamp options, ensuring compatibility with different systems. |

Ezi-Dock Powder

Handling Solutions

Overview

Ezi-Dock offers an extensive range of powder handling solutions, including chargebags and bottles, designed to meet diverse containment needs in pharmaceutical production. Each component supports safe and efficient powder transfer processes while maintaining compliance with industry standards. Designed for single-use, flexible containment, chargebags provide a cost-effective and disposable solution for handling APIs and other fine powders. Ezi-Dock chargebags come in various configurations.

EZI-DOCK EZI-FLOW™ CSV MK5

Designed for high-containment powder transfer, ensuring that materials remain fully enclosed throughout the transfer process. This system significantly reduces exposure risks and is ideal for pharmaceutical environments demanding strict containment standards.

EZI-DOCK EZI-FLOW™ CSV MK5 All Plastic

Fully plastic version of the MK5, designed for environments requiring single-use solutions. Offers secure, enclosed powder transfer while eliminating cleaning validation, making it ideal for pharmaceutical applications with strict hygiene protocols.

EZI-DOCK EZI-FLOW™ CSV MK5 VHP

Incorporating Vaporised Hydrogen Peroxide (VHP) compatibility, this variant is suited for environments requiring additional sterility controls. It is particularly beneficial in applications where microbial contamination prevention is critical.

EZI-DOCK EZI-FLOW™ CSV MK4

Designed for high-containment powder transfer, ensuring that materials remain fully enclosed throughout the transfer process. This system significantly reduces exposure risks and is ideal for pharmaceutical environments demanding strict containment standards.

EZI-DOCK EZI-FLOW™ CSV MK4 All Plastic

Fully plastic version of the CSV MK4, designed for environments requiring single-use solutions. Offers secure, enclosed powder transfer while eliminating cleaning validation, making it ideal for pharmaceutical applications with strict hygiene protocols.

Single-Use

Single-Use

Containments

Containments Mixers

Mixers

Pumps & Flow Measurment

Pumps & Flow Measurment

Valves

Valves

Seals

Seals

Hoses

Hoses

Fittings

Fittings

Tube Sealers & Welders

Tube Sealers & Welders

Transfer Ports

Transfer Ports

Validation

Validation

We utilize cookies to ensure you have the best possible experience while visiting our website.

We utilize cookies to ensure you have the best possible experience while visiting our website.