Single-use Assemblies

Romynox Assemblies

Single-use systems (SUS) are essential in modern bioprocessing due to their flexibility, efficiency, and cost-effectiveness. They significantly reduce the risk of cross-contamination and microbial issues, which is vital for producing vaccines, antibodies, recombinant proteins, and gene therapies. By eliminating the need for extensive cleaning between batches, SUS streamline the manufacturing process, enhance product safety, and facilitate faster production cycles. Their use supports high-quality outcomes in biopharmaceutical development and manufacturing.

Romynox offers a range of innovative single-use assemblies that can be customized to fit your specific processes, as well as a variety of pre-designed options. Our team has years of experience in establishing biomanufacturing processes for clients. Additionally, Romynox operates its own ISO 7 cleanroom, ensuring full control over our projects. Our single-use assembly solutions meet high standards, backed by extensive knowledge and expertise in engineering. Choose Romynox for reliable and high-quality single-use assemblies.

Biomanufacturing

As the bioprocessing landscape evolves, single-use assemblies are transforming the field by providing flexible, efficient, and cost-effective solutions for producing pharmaceuticals and biologics. These disposable systems help reduce contamination risks, lower cleaning costs, and enable faster production turnaround times. However, they also present challenges, such as increased waste and material compatibility issues. Ongoing innovations in materials and digital integration are advancing single-use technology, solidifying its role as a crucial component in modern biomanufacturing.

Standard assemblies

Standard assemblies for bioprocessing are an excellent way to accelerate your research, drug development, and manufacturing projects. Their pre-configured systems provide faster solutions with shorter lead times, making them ideal for optimizing process development and ensuring both speed and precision in your projects.

Our offerings

Romynox supplies a selection of standard assemblies. This pre-configured systems that are readily available for a wide range of applications. With no minimum order size and competitive lead times, you can choose from standard configurations or customize them to meet your specific requirements.

Customised assemblies

Bioprocessing involves a variety of processes, each requiring a unique approach. Customized assemblies play a crucial role, as they are tailored single-use systems designed to meet specific process requirements. These systems are engineered with precise configurations and components to align with your production workflows. Romynox offers tailored solutions specific to your process, supported by our team’s expertise in consulting, development, and testing. Partnering with us can accelerate your project timelines. We enhance the configuration of custom single-use assemblies based on your process type and scale, ensuring optimal performance. Our goal is to develop the solutions you need and address your bioprocessing challenges effectively.

Assemblies for all applications

In biomanufacturing, various stages and processes are involved, each playing a crucial role in the production of biological products. Romynox's Integrated Single-Use team is equipped to provide single-use systems for every stage and type of biomanufacturing process.

- Upstream Processing

- Downstream Processing

- Formulation and Fill-Finish

- Analytical and Quality Control

- Support Processes

- Process Development and Scale-Up

Materials and compatibility

We efficiently integrate your order into your project with a streamlined process from request to delivery. Our team ensures accuracy and care, tailored to your specific needs.

Our project phases

Romynox provides an optimized, cost-effective project process to deliver complete solutions tailored to your specific needs. From the initial engineering phases through product development and final delivery, our team is with you every step of the way. We focus on optimal project management, cost reduction, and streamlined execution, ensuring your projects are completed on time and within budget.

1

Step 1: Customer Inquiry

Whether you have a product design in mind or need help exploring options, request a quote. Our Sales Team will coordinate with Customer Service to get your project started.

2

Step 2: Engineering

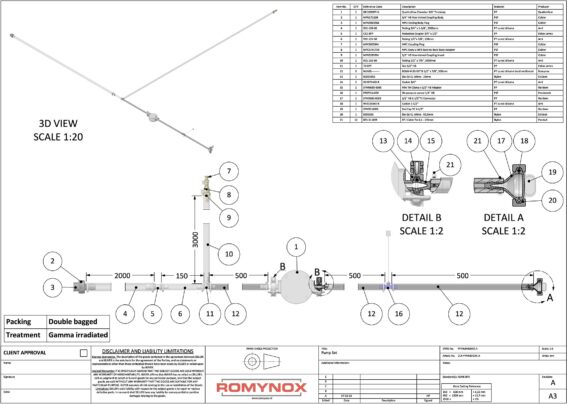

Our single-use engineers will design or refine your system to meet your process needs. We provide detailed 2D and 3D CAD designs along with a product quote.

3

Step 3: Production and Quality Control

Our experts prepare and assemble your system in our ISO 7 cleanroom. We then sterilize the system and conduct thorough quality control, including optional integrity testing.

4

Step 4: Shipping

We carefully pack and ship your single-use system worldwide. In the Netherlands and Belgium, we offer hand-delivery with our fully electric VW Buzz.

Question or interested in costumized single-use solutions?

We're ready to support you so feel free to contact us.

Customized single-use solutions for divers applications

Romynox is at the forefront of single-use technology, revolutionizing the biomanufacturing landscape with our innovative solutions. We go beyond simply supplying products by offering comprehensive end-to-end support tailored to the unique needs of each bioprocess. With a focus on agility and precision, we provide an extensive range of both customizable and pre-designed assemblies to streamline your production processes.

Our components, including tubing, connectors, and bags, are engineered for optimal performance across various bioprocessing applications. Operating in a state-of-the-art cleanroom environment, Romynox ensures that every product meets the highest standards of cleanliness and reliability. By partnering with renowned industry leaders such as Quattroflow, Sonotec, and Sebra, we deliver unparalleled quality and cutting-edge technology, ensuring seamless and efficient integration into your biomanufacturing operations.

Single-Use

Single-Use

Containments

Containments Mixers

Mixers

Pumps & Flow Measurment

Pumps & Flow Measurment

Valves

Valves

Seals

Seals

Hoses

Hoses

Fittings

Fittings

Tube Sealers & Welders

Tube Sealers & Welders

Transfer Ports

Transfer Ports

Validation

Validation

We utilize cookies to ensure you have the best possible experience while visiting our website.

We utilize cookies to ensure you have the best possible experience while visiting our website.