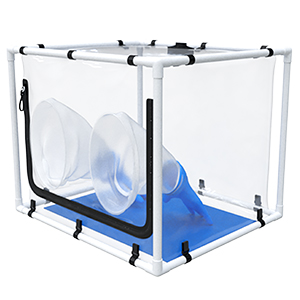

Ezi-Dock Bench-Top Isolator

Ultra-Fast Setup for Occasional Use and Small-Scale Applications

When space is limited and containment is only needed occasionally, a fast-deploying and compact solution is essential. The Ezi-Dock Bench-Top Isolator provides the perfect answer.

Designed for situations where speed and convenience matter, this isolator features an innovative pop-up design that becomes fully operational in under two minutes. It is ideal for single-use or short-term applications.

- Fast Setup

Ready for use in under two minutes. - Compact & Lightweight

Fits standard workbenches, making it ideal for space-constrained environments. - Integrated Filtration

A P3-grade air filter in the rear panel ensures safe pressure equalization. - Durable Material

Constructed from TFL-1GX polyether-based TPU film for chemical resistance and longevity. - Gas-Tight Zippers

Provide airtight containment for sensitive operations. - Electrostatic Discharge-Resistant

Smooth-finish synthetic rubber base matting prevents static build-up.

- Quick Setup and Space-Saving

The Bench-Top Isolator can be assembled within two minutes straight from the packaging, making it ideal for applications with limited space. - Durable and Flexible Construction

The enclosure and sleeves are made from TFL-1GX polyether-based thermoplastic polyurethane, with a base of electrostatically dissipative synthetic rubber. - Ergonomic Design for Safe Operation

Equipped with oval glove sleeves (300 mm x 200 mm) at the front, featuring a three-groove cuff and gloves for secure replacement in case of damage. - Easy Access and Installation

The system is set up using gas-tight zippers and supported by a lightweight frame made of 1” PVC tubing with three-way corner connectors. - Integrated Air Filtration

A P3-grade air filter in the roof panel ensures pressure equalisation during operator movements within the glove sleeves.

How to Request a Quote

Since every application is unique, these flexible isolators are typically custom designed to fit

specific user requirements. To ensure the best solution for your needs, we follow this simple

process.

- Define Your Needs - The best way to start is by creating a User Requirement Specification (URS).

- Preliminary Design – Ezi-Dock will develop an initial design proposal based on your specifications.

- Final Design & Quotation – Together, we refine the design to create a tailor-made isolator solution for your application.

Question or want to request a quote?

Feel free to contact us.

If you want to learn more about isolator solutions, have any questions, or would like to experience

their efficiency firsthand, request a free, no-obligation quote.

Phone: +31 85 043 3110

Email: info@romynox.nl

Single-Use

Single-Use

Isolators

Isolators

Mixers

Mixers

Pumps & Flow Measurment

Pumps & Flow Measurment

Valves

Valves

Seals

Seals

Hoses

Hoses

Fittings

Fittings

Tube Sealers & Welders

Tube Sealers & Welders

Transfer Ports

Transfer Ports

Validation

Validation

We utilize cookies to ensure you have the best possible experience while visiting our website.

We utilize cookies to ensure you have the best possible experience while visiting our website.