MIXERS

Mixers ensure efficient, reliable mixing with minimal downtime while maintaining strict hygiene and sterility standards in the pharmaceutical, biotech, and aseptic food and beverage industries.

Single-Use

Single-Use

Essential for pharmaceuticals, these sterile items like fittings & connectors minimize contamination risks, enhancing safety and compliance.

Crucial for pharma manufacturing, these pre-sterilized sets like Single-use bag assemblies optimize production, improving efficiency and quality.

Isolators

Isolators

Ezi-Dock's single-use flexible isolators are a cost-effective, rapidly deployable alternative to traditional stainless steel systems and a smart solution for the pharmaceutical and biotech industries, meeting the demand for adaptable and efficient containment.

Mixers

Mixers

Kest Mixers provides innovative solutions for the pharmaceutical, biotech, and aseptic food industries. Designed for efficiency and sterility, our mixers ensure reliable performance, strict hygiene, and minimal downtime, optimizing your critical processes with ease.

Pumps & Flow Measurment

Pumps & Flow Measurment

Quattroflow diaphragm pumps are ideal for (bio)pharmaceutical processes, offering precision and reliability across a wide range of applications. Paired with Sonotec’s clamp-on ultrasonic flow meters the most accurate and reliable flow meters on the market they provide precise, non-contact flow monitoring for seamless process control and optimal efficiency.

Valves

Valves

Elevate your high-purity processes with our full range of valves, precision actuators, rupture-resistant bursting discs, cutting-edge filters, dependable safety valves, and more.

Experience unique quality and reliability, ensuring the best purity and safety in every process.

Seals

Seals

In the high-purity industry, excellence is non-negotiable.

Our industry-standard seals, gaskets, O-rings, and orifice plates, guarantee unparalleled quality, precision, and service for flawless processes.

Hoses

Hoses

Experience the ultimate solution for pharmaceutical processes with our silicone and PTFE hoses, tubing, and connections. Our products offer unmatched purity, flexibility, and chemical resistance, ensuring safe and efficient operations.

Fittings

Fittings

Optimize your pharmaceutical processes with our high-quality fittings, tri clamps, quick connect couplings, and torque tools. Precision-engineered for perfection, they ensure seamless, sanitary, and efficient operations.

Tube Sealers & Welders

Tube Sealers & Welders

Transfer Ports

Transfer Ports

Validation

Validation

Meet pharma industry standards effortlessly with our validated gaskets, reliable clamps, and precise thermocouples. We guarantee quality, accuracy, and service in every critical process. Enhance your pharmaceutical processes with our trusted validation products.

Mixers ensure efficient, reliable mixing with minimal downtime while maintaining strict hygiene and sterility standards in the pharmaceutical, biotech, and aseptic food and beverage industries.

The Kest Mixers are an innovative magnetic coupled series of mixers designed for the pharmaceutical, biotech, and aseptic food and beverage industries. It offers advanced solutions, including ATEX zone mixers and models for clean rooms, which are specially designed for environments requiring strict contamination control and silent operation. With seamless CIP and SIP cleaning to maintain hygiene standards, the mixer’s dry running capability, zero particle shedding with zirconium dioxide (ZrO2), and Kest Lock connection for easy maintenance make it ideal for sterile environments and time-sensitive processes. Positioned at the bottom of the tank, it ensures maximum efficiency and reliability, making it a good solution for pharmaceutical industries requiring high-performance mixing technology.

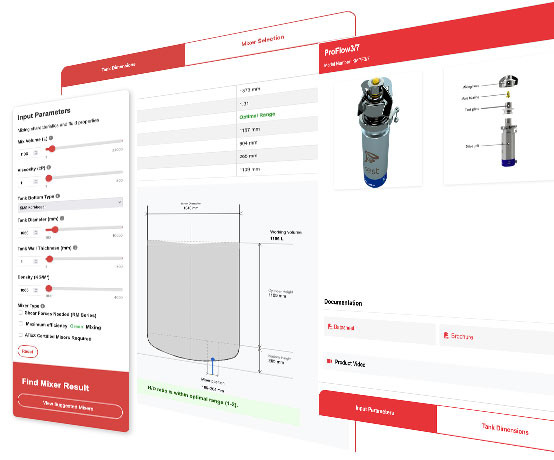

Choosing the right Kest mixer for your biopharmaceutical mixing process is now easier with our online mixer configurator. Enter your process parameters and get instant recommendations for sanitary mixing equipment that fits your needs.

Find the perfect mixer for your biopharmaceutical process:

Optimize your process & use the configurator to find the best sanitary Kest mixer for your application.

Kest Mixers are versatile and suitable for mixing a wide range of substances, including emulsions, suspensions, powders, sensitive liquids, and dispersions. They are ideal for blending two or more immiscible liquids, such as oil and water, commonly used in pharmaceutical products and cosmetics. They also effectively mix liquids with suspended solid particles, such as active ingredients in medications, or evenly distribute powders in liquids. Additionally, Kest Mixers can blend sensitive liquids, such as protein solutions in biotech processes, and create dispersions in chemical challenging applications.

Kest Mixers offer precision, reliability, and versatility for sterile environments, ensuring thorough mixing with zero contamination risk. Their CIP/SIP capabilities simplify cleaning and sterilization, saving time and maintaining hygiene. Positioned at the bottom of the tank, they maximize efficiency and prevent external contamination. Silent operation options are ideal for clean rooms, and they can handle volumes from small product recovery to 22,000 liters, providing high performance with minimal wear and energy efficiency.

Compared to mechanical seal mixers, Kest Mixers have no leakage due to their magnetic coupling, making them more hygienic and ideal for sterile applications. With fewer moving parts, they require less maintenance, reducing downtime and costs, while their robust design ensures a longer lifespan. They also perform better under extreme conditions, with no vibration or wear, and their simplified design makes cleaning and sterilization faster and easier.

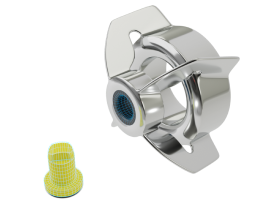

The mixer head, featuring robust Zirconium and SiC bearings, ensures zero particle shedding, confirmed by independent USP<788> testing. Its one-piece zirconium male bearing enhances aseptic design, offering superior bending strength and durability. This fine-tuned geometry guarantees low wear, robustness, and optimal performance in sterile environments. Additionally, the dry-running capability of the mixer head allows for reliable operation without lubrication, further improving efficiency and reducing maintenance needs in critical applications.

The table shows a detailed selection of mixers, each offered in various models to suit various process requirements. For each model, we provide comprehensive specifications including RPM, volume capacity, and viscosity range, allowing you to choose the perfect mixer for your needs. Whether you're working with emulsions, suspensions, powders, or sensitive liquids, our mixers are designed to deliver precision and efficiency across diverse applications, ensuring optimal performance and reliability for your processes.

Simplify the handling of your Kest Mixer with range of Kest tools: the Attractor ensures secure positioning during operation, the Bearing & Mixer Head Tool allows for smooth and precise adjustments, and the Welding Tool is perfect for achieving high-quality, reliable connections with ease.

Looking for efficient and reliable mixing solutions? Contact us today to learn how our products can meet your needs and enhance your operations with optimal performance and minimal downtime.

Phone: +31 85 043 31 10

E-mail: info@romynox.nl