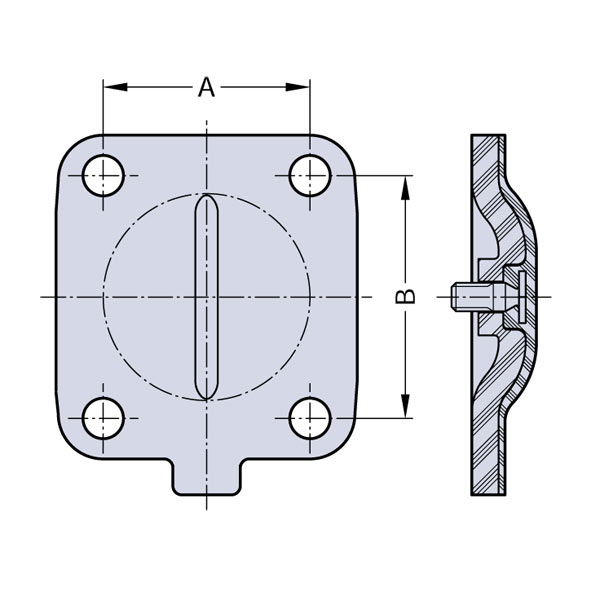

MA 40 – PTFE backed EPDM – 2-piece SED Diaphragm

DN32-40 Molded closed

Benefits

- highest degree of chemical resistance

- increased stability

- longer flex life

- less porosity

- reduced cold flow

- superior performance through temperature fluctuations between hot and cold and steam sterilization cycles.

The diaphragm is the most important component of the diaphragm valve. Besides the valve body, the diaphragm is the only part which contacts the process medium. It is the dynamic part with which the flow rate of the process medium is controlled and/or stopped.

The PTFE MA 40 two-piece diaphragm consists of a seperate EPDM backing cushion and a PTFE diaphragm. It is always molded in de closed position. This gives less tension on the diaphragm when the valve is closed, and reduces the force to close the valve which increases the life of the diaphragm.

The threaded stud is connection is embedded in the PTFE of the diaphragm. To eliminate the potential of point loading at the center of the diaphragm, a floating suspension connection to the valve operating mechanism is utilized.

All diaphragms are clearly indentified and the material is batch traceable by a set of unique codes molded into the diaphragm dvary.

Suitable for SED diaphragm valves: Steripur 417, Steripur 907, KMA 395, KMA 905, KMD 982, KMD 402

SED articlenumber: 00210.485.740.S PTFE-TM/EPDM-K code 44

Read more about Brand: SED

| Sizes | DN32 to DN40, IMP 1¼ “ – 1½ “ |

| Temp. range | -20°C to 160°C |

| Connections | Threaded stud |

| Material | PTFE backed EPDM Diaphragm (2-piece) |

| Certificates | FDA, USP Class VI {87}{88}, ISO 10993-18, TSE/BSE (ADCF), 3.1 material |

Single-Use

Single-Use

Isolators

Isolators

Mixers

Mixers

Pumps & Flow Measurment

Pumps & Flow Measurment

Valves

Valves

Seals

Seals

Hoses

Hoses

Fittings

Fittings

Tube Sealers & Welders

Tube Sealers & Welders

Transfer Ports

Transfer Ports

Validation

Validation

We utilize cookies to ensure you have the best possible experience while visiting our website.

We utilize cookies to ensure you have the best possible experience while visiting our website.