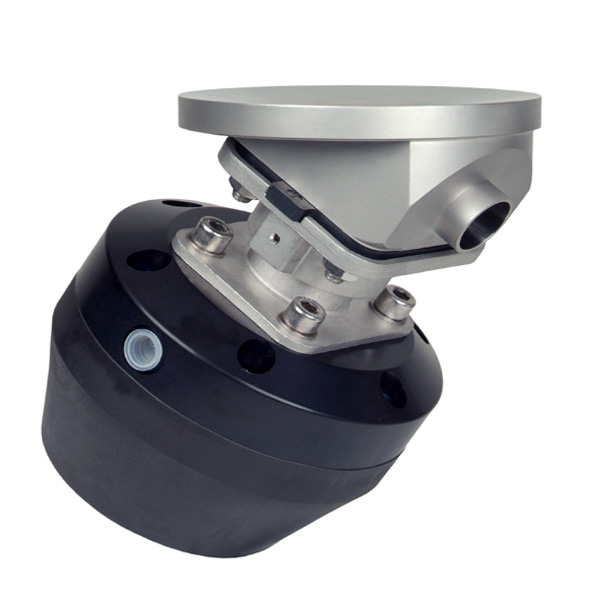

SED – Tank Bottom Diaphragm valve Customized designs

Compact stainless steel tank bottom valves

Benefits

- The tank valve body is machined as standard from solid bar stock material 1.4435/316L

- The standard design offers one valve port outlet

- Minimized dead leg and internal sump

- Suitable for mounting with SED Steripur and KMA series Actuated

The SED Tank Bottom Valve is designed for applications in the aseptic process industry offering a pocket-free interior surface, eliminating entrapment areas and minimizing flow resistance thus reducing the potential for process contamination.

The SED tank bottom valve incorporates the same features and performanceof a standard 2-way diaphragm valve from the KMA and Steripure series utilizing the same valve components for a flush mounted tank bottom valve or side mounted tank and sample valve. The SED tank bottom diaphragm valves with a casting body are unique and very affordable.

The datasheet (see below) shows some examples of standard and customized designs of tank diaphragm valves.

Read more about Brand: SED

| Sizes | 1/2″ to 4″, DN 4 to DN 100 |

| Material | – Body, connections: 1.4435 (316L) Forged or casting – Membranes: EPDM, PTFE/EPDM |

| Max. Pressure | 10 bar |

| Temp. range | -20 ºC to 140 ºC (EPDM) -20 ºC to 150 ºC (PTFE/EPDM) |

| Type of connections | Tri-clamp connection (ISO, ASME-BPE, DIN 32676), Flange, Butt Weld, Orbital Weld |

| Weld connections | ISO 1127, ASME-BPE, DIN 11850, BS-4825, SMS 3008 |

| Finishes | Interior surfaces SF1 |

| Operation | Manual or Pneumatic Actuator |

| Certificates (standard) | 3.1 material, FDA, USP Class VI 121 ºC, {87}, {88}, EHEDG, PED, CE1935/2004, TSE/BSE |

| Certificates (optional) | 2.2 surface finish, ATEX 2GD |

Options:

- Options for sampling, sterilization, and multi-outlet configurations.

- Other alloy options available as specified

- Optional manual operation via an extended crankshaft stem

Standard certificates

Optional certificates

You can contact us or ask for your Optional Certificate in your quotation.

No brochures are available at the moment.

Single-Use

Single-Use

Containments

Containments Mixers

Mixers

Pumps & Flow Measurment

Pumps & Flow Measurment

Valves

Valves

Seals

Seals

Hoses

Hoses

Fittings

Fittings

Tube Sealers & Welders

Tube Sealers & Welders

Transfer Ports

Transfer Ports

Validation

Validation

We utilize cookies to ensure you have the best possible experience while visiting our website.

We utilize cookies to ensure you have the best possible experience while visiting our website.