Choose the correct gasket and installation instruction for your reliable tri-clamp connection

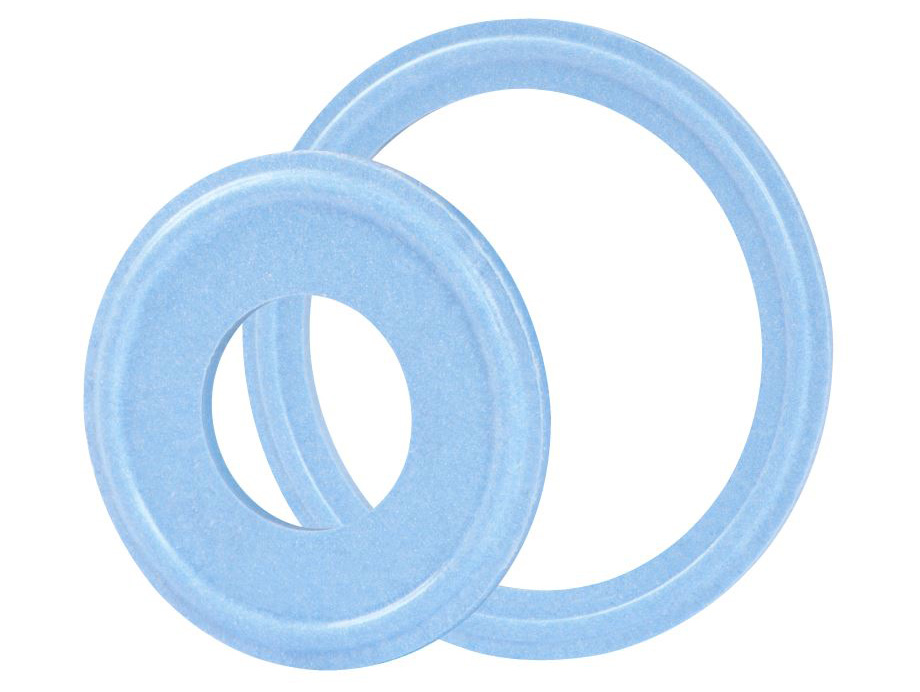

Tri-Clamp gaskets play a critical role in ensuring leak-free, hygienic connections for pumps, filters, and fittings in the biopharmaceutical industry. Choosing the correct gasket for your process is essential to maintaining system integrity and preventing contamination.

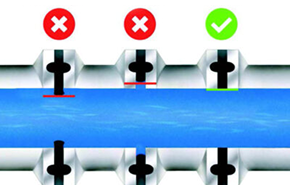

To achieve a secure and reliable seal, it’s essential to select the best gasket material for the process, follow the installation instructions, check the fittings for irregularities, ensure correct alignment of the fittings, and choose the Tri-Clamp that aligns with the process and intended use.

Select the right gasket material for the right process

What type of gaskets

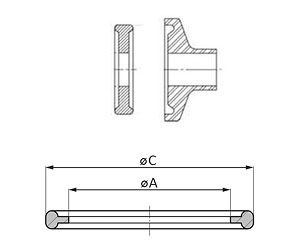

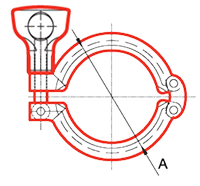

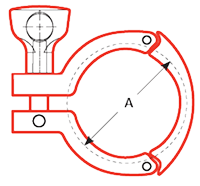

For many years, the standard Tri-Clamp seal (Type 1) was the only option available. However, when DIN and ISO adopted the Tri-Clamp standard alongside ASME, the flange type (Type 2) was introduced simultaneously as a more user-friendly and easier-to-install option.

Initially, this flange type was only available in DIN and ISO sizes, where it quickly became the new standard. Over time, it was also introduced in select ASME sizes, though the traditional Type 1 seal remains dominant in ASME applications.

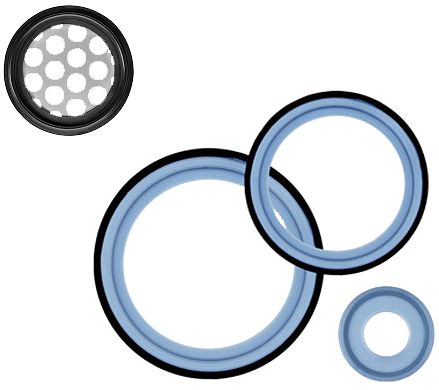

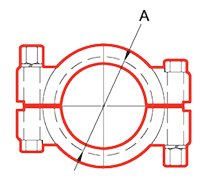

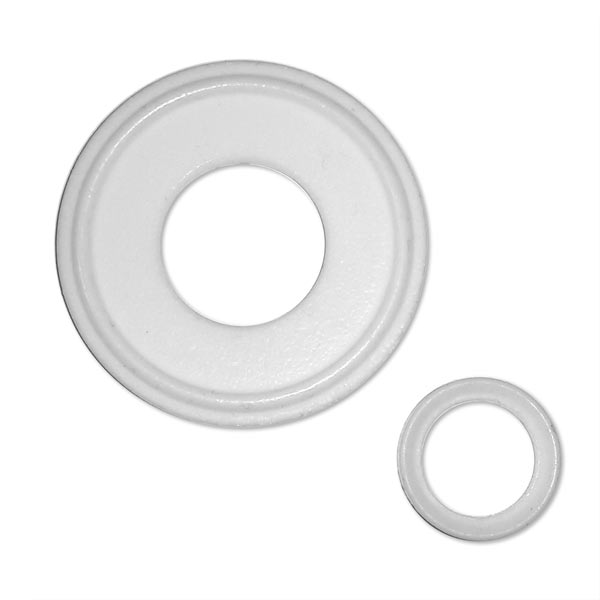

Mini

Mini Gasket

Gasket configuration

for all 25 mm flange sizes

Standard

Standard Gasket

Gasket configuration

for flange sizes except 25 mm

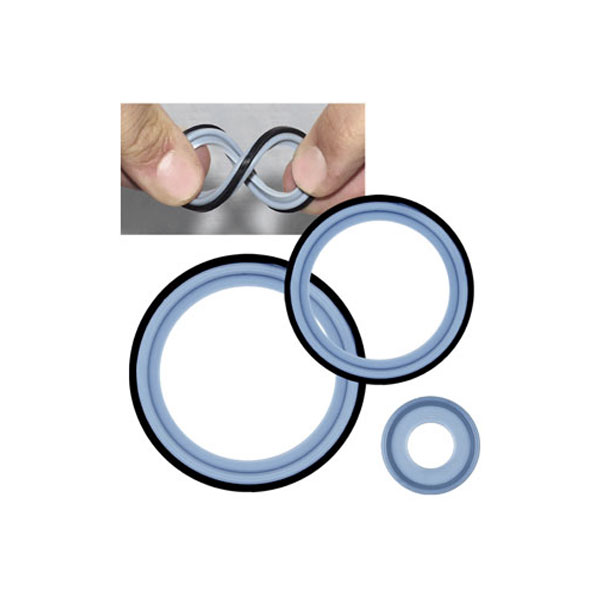

Type 1 (ISO 2852 type B)

Flanged

Flanged Gasket

Gasket configuration

for flange sizes except 25 mm

Type 2 (ISO 2852 type A)

There’s more to check regarding Tri-Clamp Gaskets to maintain a reliable & safe system

Romynox tri-clamp gauge tool – quick & easy fitting inspectionEasily check if your fittings are damaged or worn out with the Romynox Fitting Tool, ensuring a secure and reliable connection. Designed for quick and easy inspection of tri-clamp flanges.This tool helps you effortlessly check if your fittings are worn out, damaged, or out of shape, preventing potential leaks and ensuring a perfect fit every time. The tool is suitable for sizes 25 (3.36mm), 34-130 (2.84mm), 144 (3.50mm), and 155-338 (5.59mm), making it a versatile solution for various tri-clamp connections. Ideal for maintenance and service control, the Romynox tri-clamp gauge tool is a must-have for anyone working with tri-clamp fittings. |

|

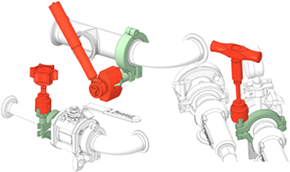

Use the right tri-clamp type to ensure a leak-free, GMP-compliant connection.

|

|||||||

Prevent gasket compression issues with the right torque tools

Precision Control

Prevent over- and under-compression with preset torque limitsEasy to Use

Click confirmation when the correct pressure is reachedAdjustable Ranges

Torque options from 9 to 70 IN-LBVersatile Compatibility

Works with various gasket materials and universal sockets

Upgrade your process with Torque Rite, Torque Knob, and Torque

Ratchet—for a secure and reliable seal every time!

Complete gasket overview with material filter options

Explore a comprehensive range of gaskets and filter by material - silicone, FKM, FFKM, EPDM, and TFM - for easy selection tailored to your needs.

FILTER BY MATERIAL

Question or want to request a quote?

Feel free to contact us.

If you're looking for tri-clamp gaskets, have a question about them or want to request a free, no-obligation quote for tri-clamp gaskets today.

Single-Use

Single-Use

Containments

Containments Mixers

Mixers

Pumps & Flow Measurment

Pumps & Flow Measurment

Valves

Valves

Seals

Seals

Hoses

Hoses

Fittings

Fittings

Tube Sealers & Welders

Tube Sealers & Welders

Transfer Ports

Transfer Ports

Validation

Validation

We utilize cookies to ensure you have the best possible experience while visiting our website.

We utilize cookies to ensure you have the best possible experience while visiting our website.