Upgrade Your NovAseptic Magnetic Mixer Bearings

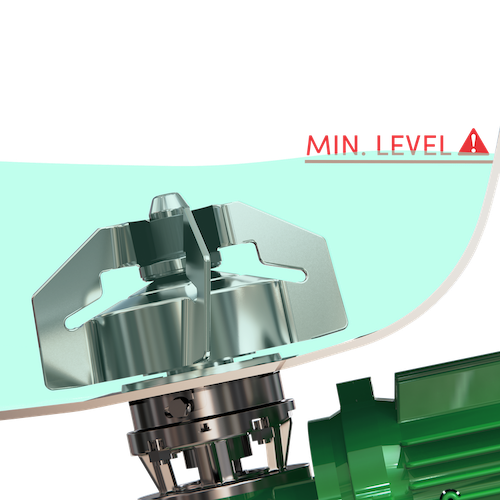

Mix until the last drop

NovAseptic® magnetic mixers are frequently used in the biopharmaceutical industry, but their silicon carbide (SiC) bearings can be fragile and prone to particle shedding. KEST® NovAseptic® style Retrofit bearings made of zirconium dioxide (ZrO2) offer a durable, wear-resistant alternative. These bearings allow mixing at low liquid levels, reducing product loss and contamination risks, while improving efficiency and extending the life of your existing mixer. Enhance your mixing performance and ensure reliable, compliant production with this advanced bearing technology.

Key Advantages of the KEST® NovAseptic® style Retrofit bearings:

- Mixing until the end

- Long lifetime

- No issues with particles in the process due to wear

Kest retrofit

Novaseptic standard

Download Rapport Partical Test

Kest Retrofit Bearing

Novaseptic Bearings

Zirconium dioxide (ZrO2) is the ideal bearing material for pharmaceutical production due to its exceptional properties. Its hardness and wear resistance ensure long-lasting performance, even in high-shear mixing environments. ZrO2 is chemically inert, preventing contamination in sensitive processes, and resists corrosion from aggressive cleaning agents like CIP and SIP systems. Additionally, its smooth surface minimizes friction and particle generation, safeguarding product purity. These qualities make ZrO2 bearings a reliable choice for maintaining the stringent hygiene and safety standards required in the pharmaceutical industry.

Certificates and Documents

Standard Certificates

Optional certificates

You can contact us or ask for your Optional Certificate in your quotation.

Interested in learning more about the minimal particle generation of our mixers? Request the report at info@romynox.nl

Product Variations

Here, you can find the right bearing for your mixer model, helping you enhance performance and ensure reliable operation.

All Variations

| RX Code | Material | Size | Mixer Type Use | OEM | Quantity | Add to Quote |

|---|---|---|---|---|---|---|

| RX Code: MKF30DZ-E----- | Zirconium Dioxide | 30mm-M12 | Novaseptic GMP 5000 - GMP 10000 - GMP 20000 | KM1-MBF30-Zr |

|

|

| RX Code: MKF20CZ-E----- | Zirconium Dioxide | 20mm-M10 | Novaseptic GMP 2000 | KM1-MB20-Zr-M10 |

|

|

| RX Code: MKF20BZ-E----- | Zirconium Dioxide | 20mm-M6 | Novaseptic GMP 500 - GMP 1000 | KM1-MB20-Zr |

|

|

| RX Code: MKF16AZ-E----- | Zirconium Dioxide | 16mm-M6 | Novaseptic GMP 100 | KM1-MB16-Zr |

|

|

| RX Code: MKF12AZ-E----- | Zirconium Dioxide | 12mm-M6 | Novaseptic GMP 50 | KM1-MB12-Zr |

|

|

Related Products

Kest's bearing and mixer head tool improve mixing system performance by reducing friction and ensuring precise control. The bearing enhances efficiency and lifespan, while the mixer head tool allows accurate adjustments, providing a reliable, low-maintenance solution for optimal mixing.

Got questions or interested in a solution? Feel free to contact us.

Do you have a question, feedback, or other information you would like to share with us?

Call or send an email. We strive to answer your question within 24 hours.

Phone: +31 85 0433110

Email: info@romynox.nl

Single-Use

Single-Use

Isolators

Isolators

Mixers

Mixers

Pumps & Flow Measurment

Pumps & Flow Measurment

Valves

Valves

Seals

Seals

Hoses

Hoses

Fittings

Fittings

Tube Sealers & Welders

Tube Sealers & Welders

Transfer Ports

Transfer Ports

Validation

Validation

We utilize cookies to ensure you have the best possible experience while visiting our website.

We utilize cookies to ensure you have the best possible experience while visiting our website.