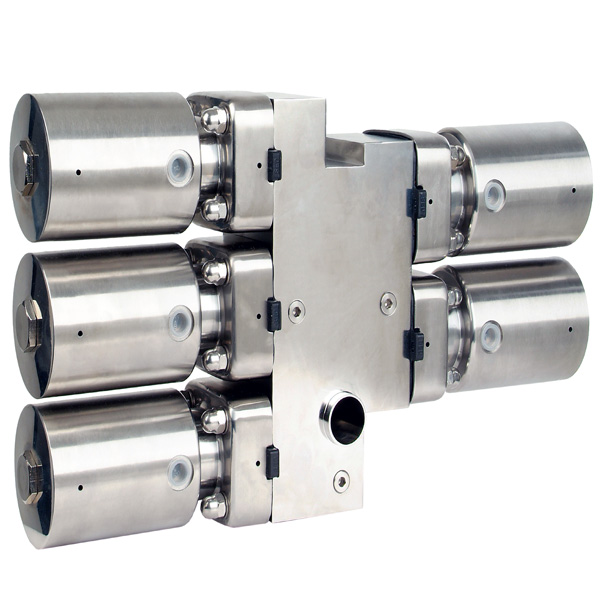

SED – Multi block Diaphragm valve

Compact multiblock with stainless steel diaphragm valves and stainless steel or plastic actuators

Benefits

- compact

- one block of stainless steel

- minimal surface contact

- faster and easier cleaning (SIP-CIP)

Romynox delivers SED multi block diaphragm valves for high purity applications in the pharmaceutical, food, fine chemical and cosmetic industries. The SED multi block diaphragm valves includes the same features and performance of a standard 2-way diaphragm valve of the KMA and Steripur series.

By using SED multiblock the diaphragm valves design process circuits can be assembled from one block of stainless steel. Due to a minimal of contact makes the system faster. And cleaning is easier (CIP –SIP). With this design seal mass will be removed as much as possible. This will increase the heat absorption and the valve assembly quickly sterile (SIP).

The multiport valves can be made in many different variations according to the wishes. For various examples see datasheet at the bottom of this page.

Options:

- Handle: control valve or open-close signaling

- Other materials: 904, Hastelloy

- Special versions: Customization is always possible

Read more about Brand: SED

| Sizes | Bore: DN 4 to DN 10 |

| Material | Body: 316L , (forged) Diaphragms: EPDM, PTFE, silicone Actuators: stainless steel or plastic |

| max temp | 150°C |

| max. presure | 10 bar |

| Connections | – Orbital welding connection with standards; ISO, ASME , DIN and SMS – Tri-clamp connection with standards; ASME BPE, DIN 32676 , DIN 11861 |

| Finish: | – surface finish Ra value to max 0.25 um – electro- polished or only mechanically polished – or ASME BPE 2012 Table SF5 |

| Operation | manual and actuator (pneumatic) |

| Certificates | 3.1, FDA , USP Class VI , CE / PED |

| Certificates (optional) | surface finish certificate, ATEX |

Standard certificates

Optional certificates

You can contact us or ask for your Optional Certificate in your quotation.

No brochures are available at the moment.

Single-Use

Single-Use

Isolators

Isolators

Mixers

Mixers

Pumps & Flow Measurment

Pumps & Flow Measurment

Valves

Valves

Seals

Seals

Hoses

Hoses

Fittings

Fittings

Tube Sealers & Welders

Tube Sealers & Welders

Transfer Ports

Transfer Ports

Validation

Validation

We utilize cookies to ensure you have the best possible experience while visiting our website.

We utilize cookies to ensure you have the best possible experience while visiting our website.