Difference between a rupture disc and a safety valve?

In general, safety valves are used more often than rupture discs. This is mostly because safety valves are already used in the system or because people are simply more familiar with this kind of pressure safety device. There are fewer people who consider rupture discs even though they are a very effective alternative. Besides, a combination of both a safety valve and a rupture disc isn’t considered very often.

There have been enough discussions and thoughts about this issue, but what are the differences exactly? To answer that, we have listed some facts for you. Watch the video to learn more about the benefits of a rupture disc or a combination of both. You can also find more information about the different options below.

SAFETY VALVE

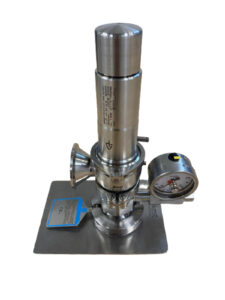

Safety valves are a type of valve that opens automatically when pressure in a process exceeds a predetermined maximum. This allows steam, gas or another medium to be blown off until the pressure drops back to the prescribed value.

Afterwards the valve closes again, but must be checked and readjusted. After this the valve can be reinstalled and the process can be resumed. The pressure can be set to any desired value.

ROMYNOX offers multiple safety valves for steam, gas, and liquids. A variety of finishes are available for the exterior and the pressure can be adjusted according to your process. The spring safety device should be installed vertically and regularly checked. This is because the spring force can decrease over time, resulting in a premature valve opening.

Rupture Disc

Rupture discs are an alternative to a safety valve. A rupture disc is fitted in the process at the same place as a safety valve. The rupture disc is set to a certain pressure.

If the pressure in the process exceeds the predetermined maximum, the rupture disc bursts open and the pressure can be released. After this, the rupture disc can be discarded and the process resumed.

ROMYNOX offers various types of rupture discs and detection system. This system sends a quick signal to the process manager about overpressure. The biggest advantage of a rupture disc compared to a safety valve is that it’s always 100% sealed. It does not have to be checked and tested in the meantime. This results in time and cost savings in the long run.

Safety Valve & Rupture Disc Combination

Safety Valve & Rupture Disc Compared

|

SAFETY VALVE |

RUPTURE DISC |

SAFETY VALVE + RUPTURE DISC |

|

|---|---|---|---|

|

Completely Closed |

NO |

YES |

YES |

|

Regular Check needed |

YES |

YES |

YES |

|

Maintenance |

YES |

YES |

YES |

|

Adjustable |

YES |

NO |

NO |

|

Takes up space |

YES |

ALMOST NONE |

YES |

|

Chance of Fluid / Dirt Accumulation |

YES |

NO |

NO |

|

Quicly replaceable |

NO |

YES |

YES |

|

Suitable for <0.5 Bar |

NO |

YES |

NOT ADVICED |

Want to know more about pressure safety?

Do you have a question or do you want advice about the ideal pressure safety device for your system?

Please contact our safety valve expert Wouter Eland or our rupture disc specialist Sierk van der Veen.

Single-Use

Single-Use

Isolators

Isolators

Mixers

Mixers

Pumps & Flow Measurment

Pumps & Flow Measurment

Valves

Valves

Seals

Seals

Hoses

Hoses

Fittings

Fittings

Tube Sealers & Welders

Tube Sealers & Welders

Transfer Ports

Transfer Ports

Validation

Validation

We utilize cookies to ensure you have the best possible experience while visiting our website.

We utilize cookies to ensure you have the best possible experience while visiting our website.